solar-plant-testingperformance-monitoring

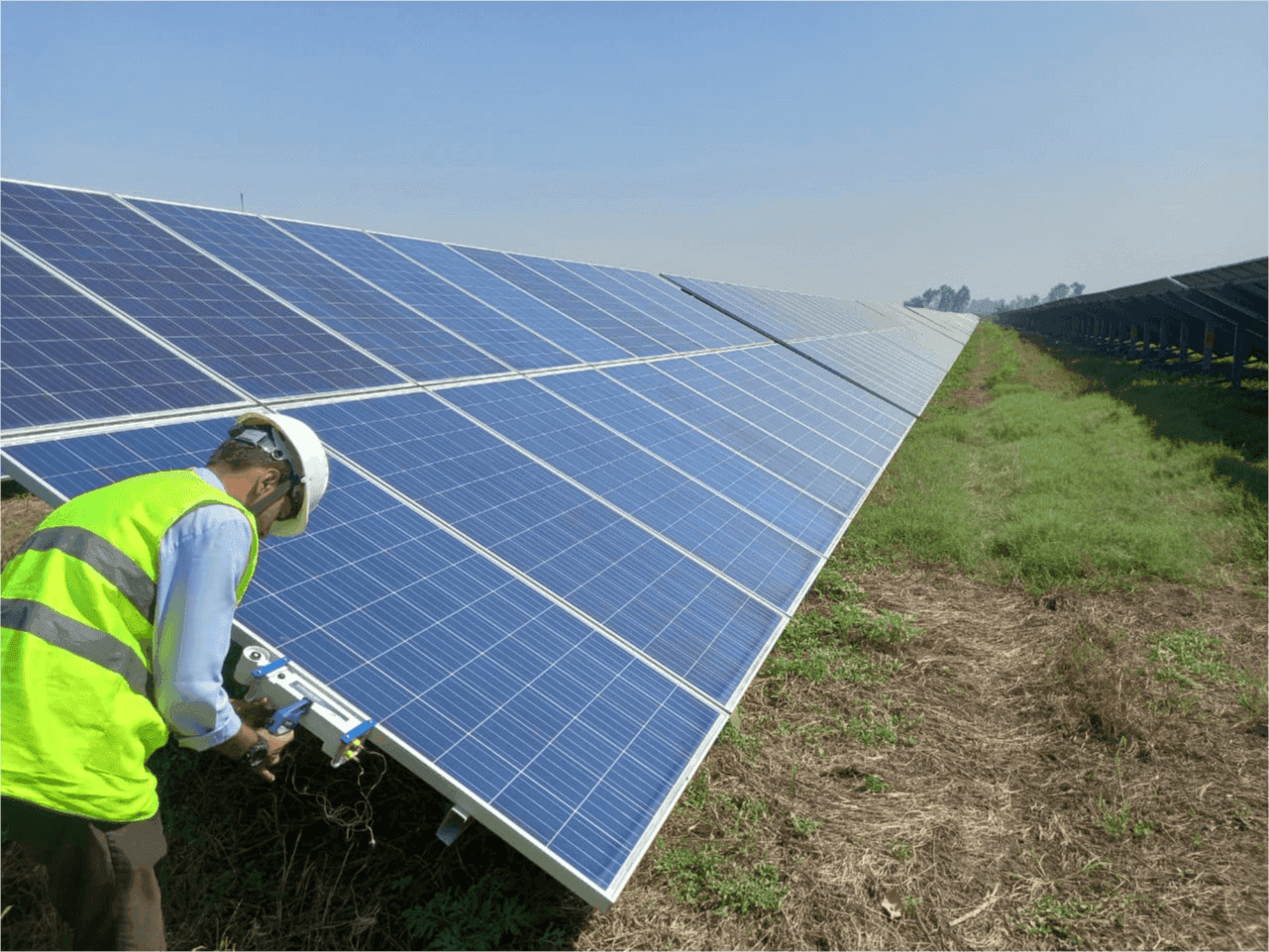

Sustainfy Energy helps maintain and increase the performance of plants with regular and effective monitoring. Though we presently carry out the assorted performance monitoring tasks manually, we plan to soon deploy a smart, IoT enabled, cloud-based system for the same. This system will help us track the performance metrics in real-time through a dashboard.

Why Choose us?

Reward Maximization

At Sustainfy Energy, we understand the importance of maximizing rewards for our clients. With our strategic solutions and expertise in renewable energy, we help you optimize your solar PV plant's performance, increasing its energy generation and overall return on investment. Trust us to unlock the full potential of your solar project and maximize the rewards it brings.

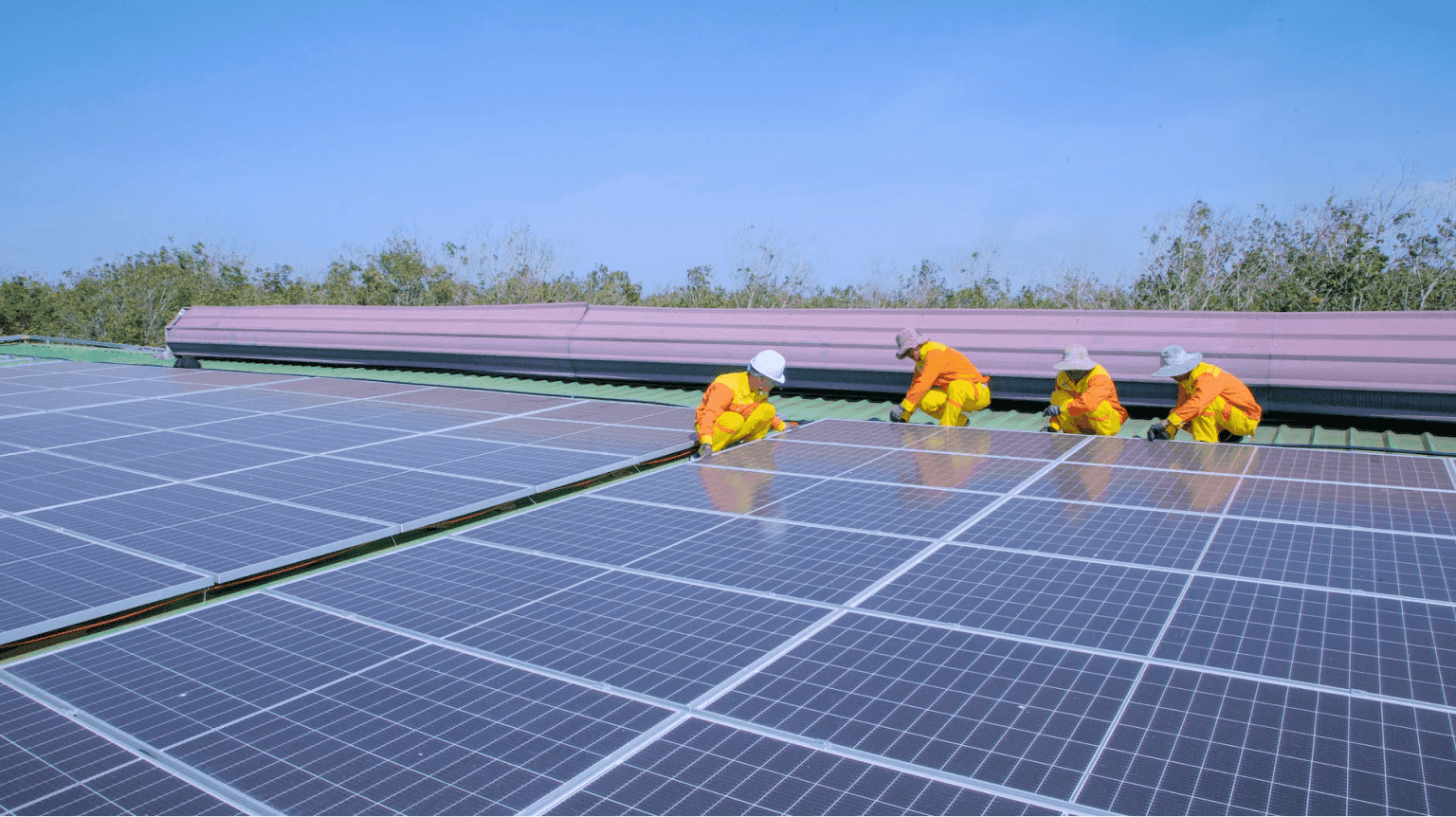

Safety Enchancement

Safety is a top priority at Sustainfy Energy. Our team of experts ensures that your solar PV plant adheres to the highest safety standards and regulations. Through rigorous inspections, testing, and design, we identify and mitigate any potential safety risks, providing you with peace of mind and a secure working environment for your solar energy operations.

Trusted by clients

At Sustainfy Energy, we have earned the trust of numerous clients in the solar PV industry. Our commitment to delivering high-quality services, exceeding expectations, and consistently delivering results has established us as a trusted partner. Join our satisfied clientele and experience the reliability and expertise that sets Sustainfy Energy apart as a trusted leader in solar PV plant inspection, testing, and design.

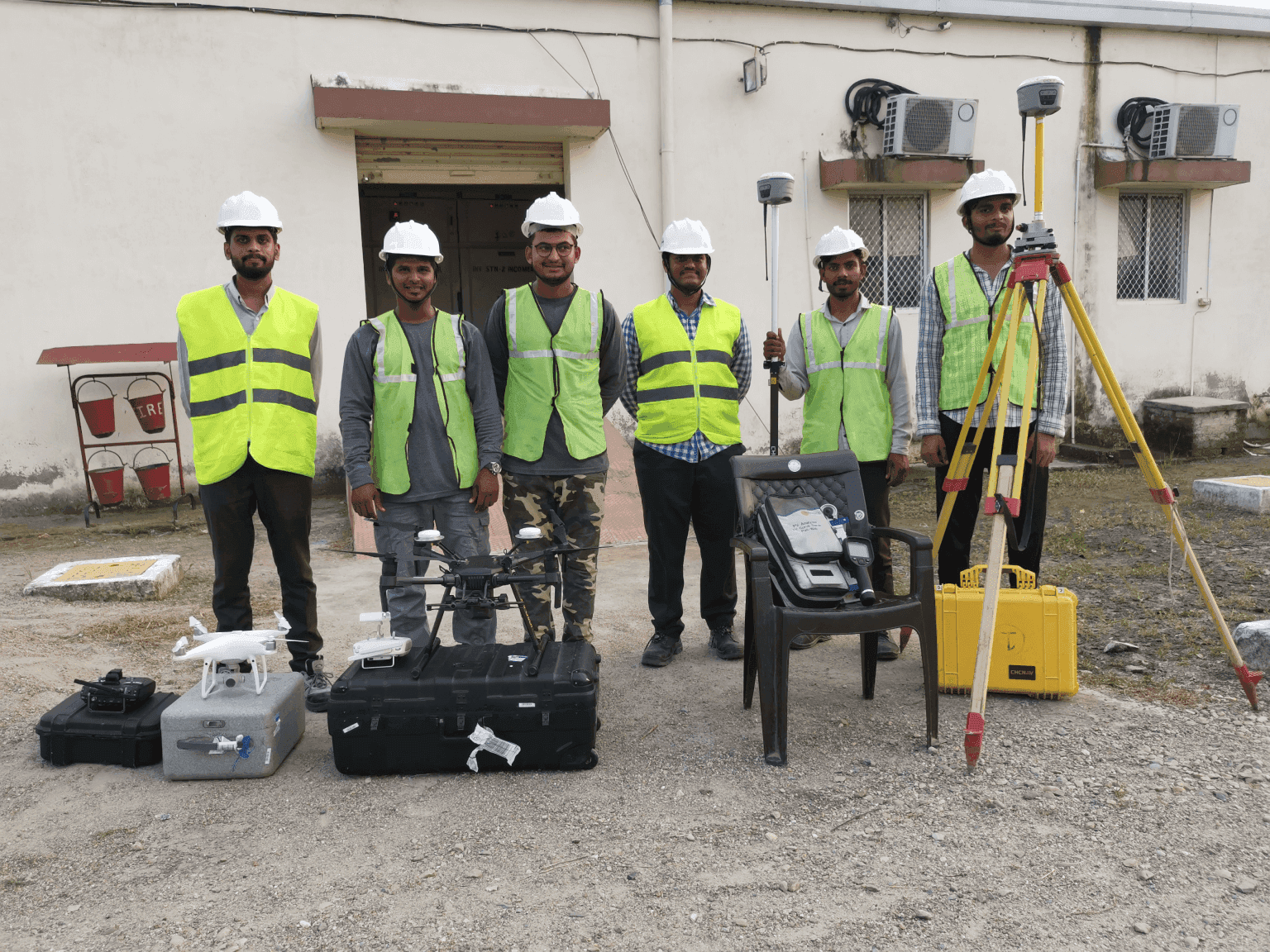

Experienced Team

With Sustainfy Energy, you have access to a team of dedicated solar experts who bring extensive knowledge and experience in the industry. Our experts are well-versed in the latest advancements and best practices, enabling us to provide you with innovative and effective solutions tailored to your specific needs. Trust our solar expertise to guide you towards achieving sustainable energy generation and long-term success.

Comprehensive services

Sustainfy Energy offers a comprehensive range of services to meet all your solar PV plant needs. From inspection and testing to design and engineering, we provide end-to-end solutions that ensure the optimal performance and longevity of your solar assets. Our holistic approach covers every aspect of your solar project, saving you time and effort by consolidating multiple services under one reliable provider.

Quality driven

Quality is the cornerstone of our services at Sustainfy Energy. We emphasize high-quality engineering, rigorous testing, and meticulous monitoring to ensure long-term performance and returns for your solar PV plant. Our quality-driven approach ensures that your investment is protected and your energy generation remains efficient and sustainable. Rely on Sustainfy Energy for uncompromising quality in every aspect of our services.

Enable your growth

Invest in Your Solar PV Plant's Success with Sustainfy Energy's Comprehensive Support

Connect NowOther Services

IV Curve Tracing Onsite

I-V Curve Tracing helps in determining the optimum combination of current and voltage for achieving maximum yield. The red line depicts maximum output achieved through the best combination of current and voltage whereas the dotted line shows reduced output, which may be a result of several factors such as a module mismatch, soiling, and more. Some key benefits of I-V Curve Tracing include:

- Lower risks during start-up and commissioning

- Thorough system performance baselines

- Effective and expedited troubleshooting

- Better performance modeling

- Detailed testing reports and analytics

- Reduced system downtime

I-V Curve Testing is a comprehensive commissioning test. SEPL carries out all commissioning services required by IEC 62446:2016. We measure the relationship between current and voltage while varying the electrical load from open circuit to short circuit, producing a characteristic current vs. voltage (I-V) curve. Measurements then are converted to STC and module performance is verified. This highly controlled test includes the following measurements: current, voltage, ambient temperature, cell temperature, irradiance, and insulation resistance.

Thermal Imaging

The solar industry has started using Infrared Thermography for detecting the underperformance in PV modules and to narrow down the faults to specific cells (Hot Spots). It is also being used for checking the uniformity oil flow in the heat exchangers of transformers and checking whether the oil is circulating as expected or there are regions of blockage by viewing the thermal image of the equipment. Similarly, this can be used to check spark or lose contacts at isolator or evacuations points or substation level of a solar power plant. So, a lot of early failures can be detected.

Key Highlights:

- Efficient method for detection of power losses

- Detection of a wide range of local faults and irregularities

- Visualization allows initial on-site evaluation

- Plant system condition monitoring over time with stored data

- Application in running installations

- State-of-the-art thermographic software for efficient reporting

- SELLP also does the Drone thermography, which can covera larger plant area

Performance Guarantee Test

One of the key requirements for a power plant owner is the performance guarantee promised by the solar installer. When the installer guarantees that a power plant will work at a certain level of efficiency and also lays out clear financial remedies in case the efficiency levels are not met, the project owner is in a much better position on his investment.

Performance guarantees and associated liquidated damage remedies allow project owners to pass the risk of an underperforming facility to the contractor responsible for designing and/or constructing it. This protection allows the project owner to make up the revenue shortfall for such under-performance so that the project company has sufficient project funds to repay its lenders & earn the expected return on equity. The technology type that a power project deploys has a significant impact on the structuring of performance guarantees & the testing used to establish whether a power facility meets such performance guarantees.

Field Testing Inverters

SEPL conducts the functional testing activity for AC and DC- side, which is helpful to claim the warranty before its warranty period comes to an end. This activity will help the client to claim the replacement/warranty for the Modules/Inverter/BOS.

AC & DC Side Testing

SEPL conducts the functional testing activity for AC and DC-side which is helpful to claim the warranty before its warranty period ends.

Regular testing of AC & DC-side equipment like Transformer, Switchyard, Control Panel, AC Protection, Solar Modules, DC-side Protection System, Inverter, SCB, Strings, etc. Is crucial, which enables us to ascertain the health of the system and its components. Eventually, this will help the client to claim the replacement/warranty for the Modules /Inverter /BOS.

EL Testing Onsite

Sustainfy Energy was engaged in an extensive Operations and Management (O&M) activity to conduct electroluminescence (EL) imaging.

Importance of EL Testing Many defects that affect solar module performance are not visible to the human eye. These defects can include micro cracks, poor/cold soldering, and broken cells, among others. For this reason, solar module manufacturers typically perform EL imaging tests to identify these defects and remove them from the production line. Following the on-site testing, Sustainfy Energy analyzed the results and identified two main defects in a large number of the modules. Those defects fell into two broad categories:

- Cold Soldering Issues

- Micro Cracks

Collectively, these defects included:

- Cracks in Silicon Solar Cells

- Cell Processing Defects (E.G. Broken Fingers)

- Silicon Quality (Lifetime) Variations

- Wire Soldering Problems

- Potential Induced Degradation

- Thin-Film Shunting

- Upgrade to PL Mode without Contacting

Benefits:

- Cost saving

- Easy inspection

© 2026 Sustainfy Energy Private Limited. All rights reserved.